Index Plunger With Flange - Steel

Indexing Plunger with Flange

OneMonroe’s index plungers with flanges are designed for mounting on thin walled parts by means of countersunk screws or rivets.

Some applications require a fixed position (Style A), whereas other applications call for a rest position, where the plunger must stay in a retracted position (Style B).

Whether you are looking for standard sizes or custom/made-to-print, we can produce a wide variety of index plungers with levers in stainless steel material (volume requirements may apply).

Have questions about our index plungers with flanges? Need a quote? Contact one of our sales engineers today for more information regarding index plungers as well as any other hardware solutions you may need.

Technical Information- Knob: High resilience Polyamide, matte finish

- Flange Body: Die-cast zinc alloy plated steel

- Plunger: Black oxidized steel with hardened end

- Application: Index Plunger with fixing plate has two holes for made for countersunk head screws

- Style A: These parts are WITHOUT rest positions

- These parts DO come with rest positions (Pull the knob and turn it by 90 degrees)

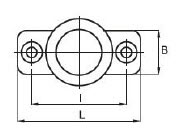

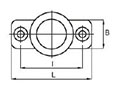

Item # |

Material |

Style |

L |

B |

D |

H |

H1 |

d1 |

I |

l2 |

|---|---|---|---|---|---|---|---|---|---|---|

| M-IPF-1000ST | Material N/A Steel | Style N/A A | L N/A 40 mm | B N/A 18 mm | D N/A 25 mm | H N/A 37 | H1 N/A 4.5 mm | d1 N/A 6 mm | I N/A 30 mm | l2 N/A 6 mm |

| M-IPF-1001ST | Material N/A Steel | Style N/A A | L N/A 40 mm | B N/A 18 mm | D N/A 25 mm | H N/A 45 | H1 N/A 4.5 mm | d1 N/A 6 mm | I N/A 30 mm | l2 N/A 14 mm |

| M-IPF-1002ST | Material N/A Steel | Style N/A A | L N/A 46 mm | B N/A 20 mm | D N/A 31 mm | H N/A 44 | H1 N/A 5.5 mm | d1 N/A 8 mm | I N/A 34 mm | l2 N/A 8 mm |

| M-IPF-1003ST | Material N/A Steel | Style N/A A | L N/A 46 mm | B N/A 20 mm | D N/A 31 mm | H N/A 54 | H1 N/A 5.5 mm | d1 N/A 8 mm | I N/A 34 mm | l2 N/A 18 mm |

| M-IPF-1004ST | Material N/A Steel | Style N/A B | L N/A 40 mm | B N/A 18 mm | D N/A 25 mm | H N/A 37 | H1 N/A 4.5 mm | d1 N/A 6 mm | I N/A 30 mm | l2 N/A 6 mm |

| M-IPF-1005ST | Material N/A Steel | Style N/A B | L N/A 40 mm | B N/A 18 mm | D N/A 25 mm | H N/A 45 | H1 N/A 4.5 mm | d1 N/A 6 mm | I N/A 30 mm | l2 N/A 14 mm |

| M-IPF-1006ST | Material N/A Steel | Style N/A B | L N/A 46 mm | B N/A 20 mm | D N/A 31 mm | H N/A 44 | H1 N/A 5.5 mm | d1 N/A 8 mm | I N/A 34 mm | l2 N/A 8 mm |

| M-IPF-1007ST | Material N/A Steel | Style N/A B | L N/A 46 mm | B N/A 20 mm | D N/A 31 mm | H N/A 54 | H1 N/A 5.5 mm | d1 N/A 8 mm | I N/A 34 mm | l2 N/A 18 mm |