OneMonroe O-rings are the industry standard for sealing solutions, offering simplicity, durability, and efficiency across a wide range of applications. Designed to handle pressures up to 3000 PSI, these seals are easy to install and can function effectively as double-acting seals, ensuring dependable performance under demanding conditions. When working with pressures above 800 PSI, back-up rings can be incorporated to enhance stability based on specific operating conditions and gland design. While ideal for static and reciprocating applications, O-rings are not recommended for rotary uses, as they tend to rotate with the shaft and may cause leaks; for rotary functions, lip seals are a better choice.

Each OneMonroe O-ring is available in various sizes, specified by inside diameter and cross-section dimensions, ensuring that you can find the exact fit for your needs. In cases where non-standard sizes are required, we offer customized dimensions, though tooling charges may apply. Our O-rings are manufactured with different compounds and durometer hardness options to best suit the application environment, making them a versatile choice for various industries. They are widely used in biotech, food and beverage processing, medical equipment, and pharmaceuticals, meeting strict industry standards for performance and quality.

With a comprehensive range of resources, OneMonroe provides the necessary tools and guides to help you make informed choices for your O-ring needs. From our Comparison Properties Chart to our PTFE Encapsulated O-rings and O-ring Groove Design Chart, we provide everything you need to select the most suitable sealing solution for your specific application. OneMonroe’s commitment to high-quality materials and innovative design ensures that our O-rings deliver superior sealing performance, helping to keep your systems running smoothly and efficiently in even the most challenging conditions.

O-rings are commonly used in the Biotech, Food & Beverage, Medical, and Pharmaceuticals industries. Updated: 10/18/19 For more information, please see: Comparison Properties Chart, PTFE Encapsulated O-rings, Material Shelf Life, and O-ring Groove Design Chart.

/Asset/oring61.jpg

Discover the pinnacle of sealing solutions with OneMonroe, your premier manufacturer and supplier of top-tier O-rings, gaskets, seals, extrusions, and an array of molded products. With an extensive selection of compounds and cutting-edge machinery at our disposal, OneMonroe Seals stands ready to fulfill virtually any design requirement with precision and expertise.

Our seals find indispensable utility across a spectrum of industries, including Aerospace, Agriculture, Food & Beverage, Medical, and Pharmaceuticals. Engineered to excel in even the most demanding environments, our seals guarantee unparalleled performance, reliability, and longevity.

Crafted with a steadfast commitment to quality and innovation, OneMonroe seals undergo rigorous testing to ensure compliance with the highest industry standards. From hydraulic to pneumatic applications, our seals are meticulously designed to withstand extreme temperatures, pressures, and operating conditions. Experience peace of mind knowing that OneMonroe Seals are backed by our dedication to excellence, pushing the boundaries of seal technology to optimize efficiency and minimize downtime. Explore our comprehensive catalog today and discover the seal that perfectly aligns with your specific needs and expectations.

/Asset/OilSeal.jpg

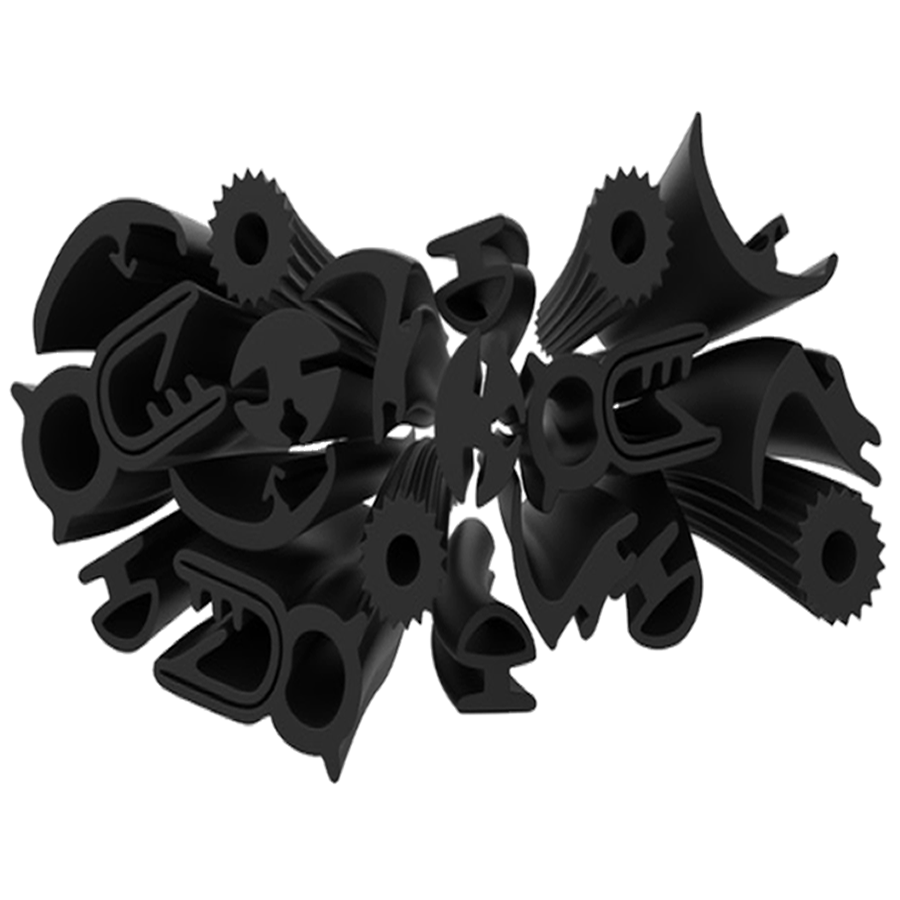

Monroe’s extruded seals are engineered to meet the diverse needs of various industries, offering reliable sealing solutions for a wide range of applications. From architectural door and window seals to automotive, aerospace, and appliance components, our extrusions provide critical functionality in manufacturing and assembly processes. Designed for durability and performance, our seals serve as bearing seals, bumpers, heater gaskets, vacuum cleaner belts, radiator overflow tubing, ladder foot grips, and much more. With an extensive selection of extrudable materials, we deliver customized solutions that enhance efficiency, safety, and longevity in demanding environments.

As industries continue to innovate, the demand for high-quality extruded seals is rapidly expanding. At Monroe, we stay ahead of the curve by providing advanced extrusion solutions tailored to meet unique design and performance requirements. Whether you need standard profiles or custom-engineered seals, our expert team ensures precision manufacturing and material selection to optimize your application’s performance. Trust Monroe for high-performance extrusions that deliver superior sealing, protection, and durability in even the most challenging conditions.

/Asset/extrusions-fw.png

Custom Molded parts are very design specific. Whether they are compression, injection or transfer molded, OneMonroe Seals has years of experience providing customers with custom molded parts that are unique to their application. Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. Monroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides. Updated: 10/26/20

/Asset/Molded.jpg

Gasket applications cover a large spectrum of materials ranging from acrylic and aluminum to Viton® and PTFE. Your gasket manufacturing options are as varied as Die Cutting, Lathe Cutting, Kiss Cutting and Rotary Cutting. Not all methods will produce the same tolerances and some materials only lend themselves to certain methods of manufacturing. Perhaps you have a critical dimension, this may require a hardened steel tool or perhaps it will be best produced by water jet cutting or even molding.

Gasket applications cover a large spectrum of materials ranging from acrylic and aluminum to Viton® and PTFE. Your gasket manufacturing options are as varied as Die Cutting, Lathe Cutting, Kiss Cutting and Rotary Cutting. Not all methods will produce the same tolerances and some materials only lend themselves to certain methods of manufacturing. Perhaps you have a critical dimension, this may require a hardened steel tool or perhaps it will be best produced by water jet cutting or even molding.

Gaskets can also be produced from extruded rubber profiles cut to length and vulcanized to form continuous custom gaskets. For larger gaskets we can incorporate interlocking or “dove tailed” parts. Many of the materials listed below can be offered with pressure sensitive adhesives on one or both sides, when bolt holes or mounting pins are not an option.

Let OneMonroe Seals be the source for all your gasket requirements. Contact us and we will put our experts to work for you. Our knowledgeable sales staff will assist you in pairing the right gasket material with the right manufacturing process.

For more information, including technical guides, please look at our seals guides

/Asset/Gasket.jpg

Introducing OneMonroe's premium rubber sheeting, crafted to elevate your industrial operations to new heights of efficiency and reliability. Engineered with precision and durability in mind, our rubber sheeting is designed to excel in a myriad of applications across various industries.

From manufacturing to construction, our product serves as a versatile solution, providing exceptional performance in sealing, cushioning, and insulating applications. Its superior resilience and resistance to abrasion ensure longevity, reducing downtime and maintenance costs. Whether in automotive, aerospace, or marine sectors, our rubber sheeting guarantees optimal functionality, even in the most demanding environments.

Experience peace of mind with OneMonroe's rubber sheeting, knowing you have a dependable solution that enhances productivity and safety. With customizable options to suit specific needs and stringent quality control measures, our product delivers consistent results, earning the trust of professionals across industries worldwide. Elevate your operations with OneMonroe and discover unparalleled performance and durability.

/Asset/rubber-matting.jpg

Manufacturing Capabilities and Design Options |

||

|

|

|

Membrane Switches

OneMonroe Seals offers a diverse selection of high-performance membrane switches that serve the needs of industries such as Defense, Aerospace, Consumer, Industrial, and beyond. Designed to meet rigorous quality standards, including FDA compliance, our membrane switches are constructed using flexible materials, reinforced with stainless steel domes over each switch position, and bonded to a rigid surface. This durable design ensures reliable operation, exceptional tactile feedback, and long-lasting performance in even the most demanding applications.

Our extensive manufacturing capabilities and design options enable us to deliver tailored solutions that match our clients’ exact requirements. From prototyping and CAD/CAM design to advanced techniques like UV-resistant ink technology and embedded LEDs, we provide a full spectrum of customization features. Additional capabilities include EMI/RFI shielding, sub-surface printing, die cutting, embossing, and more—ensuring that every membrane switch we produce is optimized for functionality, durability, and visual appeal.

/Asset/membrane-switch2.jpg

NEED custom manufacturing? WE are the experts. REQUEST RFQ