OneMonroe is a direct manufacturer and supplier of custom molded rubber parts. OneMonroe Seals molding processes include: transfer, injection, and compression molding to accommodate any size or volume requirements. Contact us with your design specifications.

OneMonroe is a direct manufacturer and supplier of custom molded rubber parts. OneMonroe Seals molding processes include: transfer, injection, and compression molding to accommodate any size or volume requirements. Contact us with your design specifications.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. Monroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides. Updated: 10/26/20

/Asset/custom-molded-rubber.jpg

Rubber bumpers, also referred to as grommet bumpers, recessed bumpers, or stem bumpers, are great for protecting products and machinery. OneMonroe Seals ensures that every bumper that we manufacture is custom designed for your particular application to guarantee the best solution.

Rubber bumpers, also referred to as grommet bumpers, recessed bumpers, or stem bumpers, are great for protecting products and machinery. OneMonroe Seals ensures that every bumper that we manufacture is custom designed for your particular application to guarantee the best solution.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. Monroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides.

/Asset/rubber-bumpers.jpg

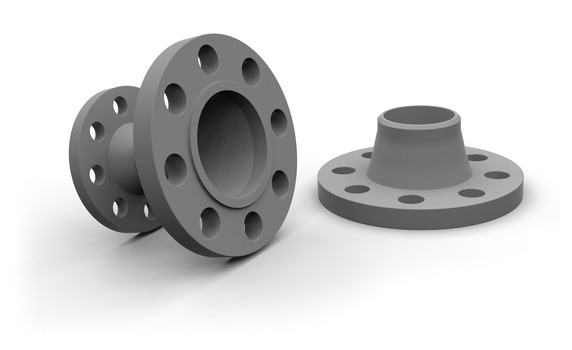

OneMonroe is a direct manufacturer and supplier of custom molded plastic parts. OneMonroe Seals molding processes include: injection, transfer, and compression molding to accommodate any size or volume requirements. Contact us with your design specifications.

OneMonroe is a direct manufacturer and supplier of custom molded plastic parts. OneMonroe Seals molding processes include: injection, transfer, and compression molding to accommodate any size or volume requirements. Contact us with your design specifications.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. Monroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides.

/Asset/custplasticparts.jpg

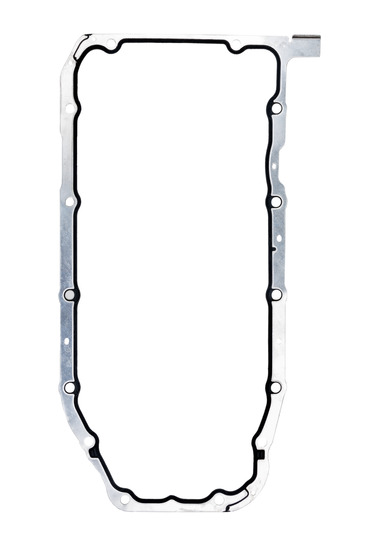

Rubber to Metal Bonding not only simplifies the supply chain process, but it also creates a robust adhesion that is stronger than the original elastomer. OneMonroe Seals's chemical experts are capable of producing high quality rubber to metal bonds for your industrial needs.

Rubber to Metal Bonding not only simplifies the supply chain process, but it also creates a robust adhesion that is stronger than the original elastomer. OneMonroe Seals's chemical experts are capable of producing high quality rubber to metal bonds for your industrial needs.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. Monroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides. Updated: 10/26/20

/Asset/rubbertometal.jpg

Grommets, also known as eyelets, are typically used to protect cabling or wire from wear and tear on a sharp edge or material. They can also be used for vibration control and are extremely easy to install. OneMonroe Seals offers an assortment of high quality, molded grommets in various materials and sizes.

Grommets, also known as eyelets, are typically used to protect cabling or wire from wear and tear on a sharp edge or material. They can also be used for vibration control and are extremely easy to install. OneMonroe Seals offers an assortment of high quality, molded grommets in various materials and sizes.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. OneMonroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides. Updated: 10/26/20

/Asset/grommets.jpgOneMonroe Seals offers both rubber and plastic caps for your protection needs. Using top of the line injection molding techniques, we can supply you with custom designed caps to fit over any component you need protected or covered. Contact us with your design specifications and application so we can find the perfect material to fit your requirements.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. OneMonroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides. Updated: 10/26/20

/Asset/caps.JPG

Plugs can be used for a variety of applications for your product including: protection, masking, appearance finishing and sealing. OneMonroe Seals has been a proud supplier of plugs to a wide variety of industries for over 40 years. Let us become your plug supplier! Contact us with your product specifications.

Plugs can be used for a variety of applications for your product including: protection, masking, appearance finishing and sealing. OneMonroe Seals has been a proud supplier of plugs to a wide variety of industries for over 40 years. Let us become your plug supplier! Contact us with your product specifications.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. OneMonroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides. Updated: 10/26/20

/Asset/rubber-plug.jpg

OneMonroe produces and supplies anti-vibration rubber mounts for industrial applications across many different industries. Wether you are looking to reduce vibration transference or simply provide a more stable base to your product, OneMonroe Seals has the capabilities to provide you with exactly the right mount for your application requirements.

OneMonroe produces and supplies anti-vibration rubber mounts for industrial applications across many different industries. Wether you are looking to reduce vibration transference or simply provide a more stable base to your product, OneMonroe Seals has the capabilities to provide you with exactly the right mount for your application requirements.

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. Monroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides.

/Asset/rubber-bumpers.jpg

Crutch tips are an essential component in the crutch assembly, providing traction to the ground and stabilizing the crutch for easy maneuverability. OneMonroe Seals offers a wide variety of standard and custom molded crutch tips in many shapes and sizes. Contact us today with your requirements and we will find the right crutch tip for you!

Crutch tips are an essential component in the crutch assembly, providing traction to the ground and stabilizing the crutch for easy maneuverability. OneMonroe Seals offers a wide variety of standard and custom molded crutch tips in many shapes and sizes. Contact us today with your requirements and we will find the right crutch tip for you!

Our broad production molding capabilities, industrial know-how and our experience in rubber formulations position us to be a leading cost effective manufacturer. OneMonroe can manufacturer in a wide-variety of materials. We also have customers in a wide-range of industries including: Medical, Transportation, Defense, Aerospace and more. Our custom molding capabilities include: injection, transfer, and compression molding to accommodate any size or volume requirements (see custom molded capabilities). Our custom molded part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports.

For more information, including technical guides, please look at our seals guides. Updated: 10/26/20

/Asset/crutchtips.jpg

NEED custom manufacturing? WE are the experts. REQUEST RFQ