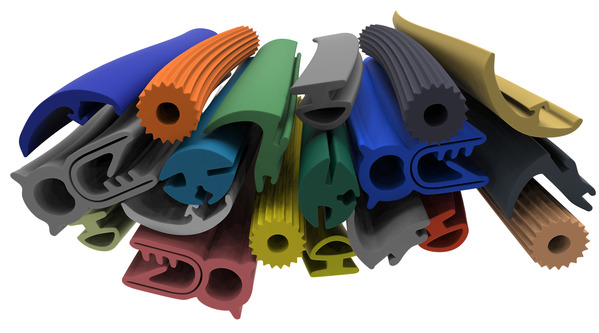

OneMonroe is capable of manufacturing custom rubber extrusions in a multitude of materials. Extrusions serve a multitude of industries including: construction, electrical, and transportation. We have state of the art machinery to get the job done quickly and efficiently. Contact us with your profile specifications and dimensions.

OneMonroe can extrude many shapes including: U channels, P strips, solid & hollow D profiles and custom shapes. We can utilize many materials including both dense and sponge materials. We work with a wide variety of natural and synthetic products. This includes: flame-retardant, food-safe & high-temperature compounds to meet your specifications. Commonly extruded materials include silicone, nitrile, EDPM, SBR, Neoprene and more.

Our extruded rubber part experience incorporates the certification of the material within the confines of each specification, while meeting and overseeing necessary quality reports. For more information, including technical guides, please look at our seals guides. Updated: 10/26/20