OneMonroe's End Caps and Conveyor Bearings are the backbone of smooth and efficient material handling systems. These essential components find applications in a wide range of industries, including manufacturing, distribution, and logistics. From conveyor belts to assembly lines, these bearings ensure seamless movement, reducing friction and enhancing operational efficiency.

OneMonroe's End Caps and Conveyor Bearings are the backbone of smooth and efficient material handling systems. These essential components find applications in a wide range of industries, including manufacturing, distribution, and logistics. From conveyor belts to assembly lines, these bearings ensure seamless movement, reducing friction and enhancing operational efficiency.

Our one-piece Thrust Ball Bearing assemblies accept greater axial thrust loads in one direction at moderate speeds with minimal radial load. Available in standard inch or metric sizes. All information based on acetal races with glass or stainless steel balls. Other materials and custom sizes are available. Monroe’s non-corrosive line of Conveyor Bearings (End Cap Bearings) offers a quiet, low friction, no maintenance alternative. Designed as an easier fit to standard size tubes and rollers, they can be washed down and require no lubrication. Ratings are based on acetal races and stainless steel balls. Other materials are available.

Featuring robust construction and precision engineering, our End Caps and Conveyor Bearings offer exceptional durability and reliability. Their high load-bearing capacity and resistance to wear and tear make them ideal for heavy-duty applications, minimizing downtime and maintenance costs. With easy installation and low maintenance requirements, they streamline operations and boost productivity across various industrial settings.

With a focus on quality and performance, OneMonroe's End Caps and Conveyor Bearings are designed to meet the rigorous demands of modern businesses. Whether it's optimizing workflow in a manufacturing plant or streamlining material handling processes in a warehouse, these bearings deliver superior performance, ensuring smooth and uninterrupted operations for our customers.

/Asset/EC437-2.jpg

OneMonroe's Thrust Bearings stand as the pinnacle of industrial efficiency, meticulously designed to meet the demands of a wide array of applications. From heavy-duty machinery to precision instruments, these bearings ensure optimal performance and reliability, even under the most rigorous conditions. With their robust construction and advanced engineering, they provide unparalleled support, reducing friction and wear while maximizing operational longevity.

OneMonroe's Thrust Bearings stand as the pinnacle of industrial efficiency, meticulously designed to meet the demands of a wide array of applications. From heavy-duty machinery to precision instruments, these bearings ensure optimal performance and reliability, even under the most rigorous conditions. With their robust construction and advanced engineering, they provide unparalleled support, reducing friction and wear while maximizing operational longevity.

Our one-piece Thrust Ball Bearing assemblies accept greater axial thrust loads in one direction at moderate speeds with minimal radial load. Available in standard inch or metric sizes. All information based on acetal races with glass or stainless steel balls. Other materials and custom sizes are available. These bearings find their place in various industries, including automotive, aerospace, and manufacturing, where precision and durability are paramount. Their ability to handle axial loads with ease makes them indispensable in applications such as gearboxes, turbines, and pumps, where smooth and efficient operation is crucial for maintaining productivity.

Featuring superior materials and precision manufacturing, OneMonroe's Thrust Bearings offer numerous benefits, including reduced maintenance costs, enhanced equipment lifespan, and improved overall performance. Their versatility and reliability make them the go-to choice for businesses seeking to optimize their operations and stay ahead in today's competitive market.

/Asset/monroe-thrust-bearing.jpg

OneMonroe's Flanged Bearings are built to tackle the demanding conditions of industrial environments. With their sturdy construction and precise engineering, these bearings excel across a wide range of sectors including manufacturing, automotive, and aerospace. They deliver reliable performance and durability, ensuring seamless operation even in challenging settings such as conveyor systems and machinery components.

With a flanged design, these bearings offer improved stability and alignment, reducing the risk of misalignment and premature wear. This not only enhances operational efficiency but also cuts down on maintenance needs, saving valuable time and resources for businesses. Boasting exceptional load-bearing capacity and resistance to corrosion, OneMonroe's Flanged Bearings guarantee long-term reliability, establishing them as the go-to choice for industrial applications.

When it comes to withstanding wet, corrosive environments, look no further than our plastic flanged ball bearings. Lightweight and engineered with precision, they surpass traditional bearings' limitations. Crafted from materials like Acetal, Nylon, and more, they're tailored to your needs, ensuring optimal equipment performance. Plus, when paired with stainless steel or non-metallic balls, they remain entirely non-magnetic, making them an ideal solution when magnetic distortion must be avoided.

/Asset/monroe-flange-bearing2.jpg

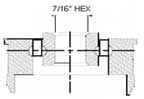

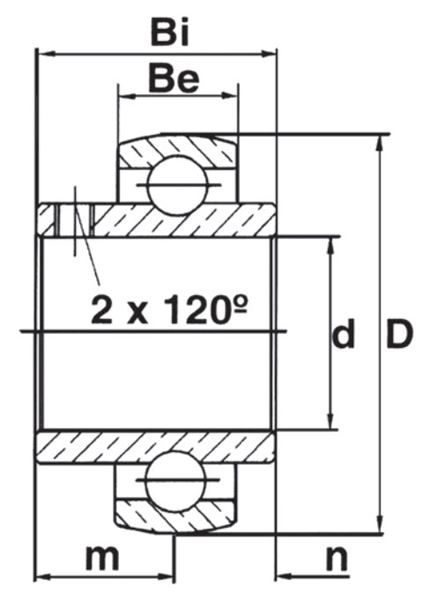

Our self-aligning insert bearings are the perfect replacement for typical self-aligning metal insert bearings. Engineered with versatility in mind, they excel in various industrial applications, from agricultural machinery to conveyor systems. Available in non-metallic and non-corrosive materials, they perform equally well in standard cast iron and our thermoplastic housings.

Our self-aligning insert bearings are the perfect replacement for typical self-aligning metal insert bearings. Engineered with versatility in mind, they excel in various industrial applications, from agricultural machinery to conveyor systems. Available in non-metallic and non-corrosive materials, they perform equally well in standard cast iron and our thermoplastic housings.

Choose from either ball bearing or bushing styles to suit your specific needs. Our bearings boast exceptional load-bearing capacity and resistance to harsh conditions, minimizing the risk of premature wear and damage. With easy installation and low maintenance requirements, they offer cost-effective solutions for businesses across industries.

At OneMonroe, quality and reliability are paramount. Our self-aligning insert bearings undergo rigorous testing and quality control measures to ensure consistent performance. Trust in our bearings to deliver exceptional results and extended bearing life in demanding environments.

/Asset/conveyor-bearing-image.jpg

Our plastic ball bearings offer a versatile alternative for various applications, particularly in environments prone to moisture and corrosion. Ideal for wash-down areas where conventional bearings risk rusting, our plastic ball bearings excel in durability and resilience. Additionally, in corrosive environments where chemical abrasiveness is a concern, these bearings provide reliable performance, ensuring longevity and efficiency.

Whether your machinery operates at low loads and RPM or handles heavy industrial equipment, Monroe Engineering provides the perfect bearing solution to keep your operations running smoothly. Even in scenarios where bearing lubrication access is challenging, our self-lubricating bearings eliminate maintenance hassles, guaranteeing continuous performance and peace of mind.

Partner with Monroe Engineering for access to high-quality plastic ball bearings tailored to your specific needs. Our commitment to innovation and customer satisfaction ensures that your machinery operates optimally, even in the most demanding environments. Trust in our expertise and reliability to enhance the performance and longevity of your equipment.

/Asset/monroe-radial-bearing.jpg

OneMonroe Bearing Housings – made of high-grade solid PBT thermoplastic polyester – are the durable, corrosion-resistant replacement for conventional metal housings. These maintenance-free housings have excellent mechanical strength, stiffness and dimensional stability – and they’ll never rust or corrode. Yet they can be cleaned or hosed down with hot water and will operate at temperatures up to 280°F.*

Compare our smooth surfaces with the rough surfaces on metal housings and you’ll see how those surfaces can harbor dirt, mold or bacteria. There’s no plating or coating to chip or peel and their solid construction means no vulnerable parts to expose.

Monroe housings can be supplied with steel or plastic ball bearings, or plastic bushings – they’re available in standard size units which accept standard-size insert ball bearings. Plastic bearings and bushings are self-lubricating and do not require lubricant. Housings can be ordered with or without bushings. Bushings are only available in plastic. Standard housing color is black, but they are also available in white.

/Asset/monroe-bearing-housing-collage.jpg

OneMonroe provides custom manufacturing solutions to clients throughout the world. We can manufacture built-to-order parts, custom products and offer a wide variety of options to solve your problem. We can support high volumes and short-lead times.

Monroe Engineering Products is a full-service manufacturer of fabricated metal assemblies and hardware. We offer a diverse product line of off-the-shelf hardware and can custom manufacture our entire product lines to match your needs. We do vendor-managed inventory (vmi) on low-cost hardware items and manage larger fabrication programs from blueprint to delivery.

/Asset/CUSTOMQUOTE_BUTTON.jpgNEED custom manufacturing? WE are the experts. REQUEST RFQ